Sustainability

A pioneer in innovation and technology, Jupiter Hospital adheres to the use of leading edge modalities for state of the art, precision-based treatments, that are at par with international standards.

An energy-efficient Hospital: How do some innovative steps bring in Operational efficiency?

An energy-efficient hospital is a key to excellence in Healthcare Sectors by Mr. Neelesh Shinde - Chief Technical Officer, Jupiter Hospital)

Why did we think of an Energy Efficient Hospital?

Since 2007 Jupiter Hospital, Thane ( Tertiary care) became operational. During the first few years of operations, we understood that running cost for Energy consumption is too high and observation was that HVAC (Heating, ventilation and air conditioning) system was contributing more than 55% of the entire consumption. In 2013 Management decided to build up Jupiter Hospital at Baner Pune. We made up our mind to have a robust HVAC system that can efficiently control energy consumption Dr. Ajay Thakker (Chairman & MD) communicated our thought process with an Energy expert. He advised us to send architectural drawings to The Indo

Swiss Building Energy Efficiency Project (BEEP). In 2014 BEEP accepted our

proposal of designing of HVAC system & they also assured us that they would take active participation in the execution & actual performance phase. A lot of discussions happened among us. Across India BEEP has designed only one hospital ( Ie Jupiter Hospital Pune ) under energy efficiency project. A lot of charrettes happened. Charrettes included brainstorming discussion for a minimum of 3 days on energy efficiency measures that need to be executed in Jupiter Hospital, Pune project. Jupiter MD, Myself, project architect, services consultant and BEEP representatives were active participants of all these charrettes.

How to improve the energy efficiency of the HVAC system?

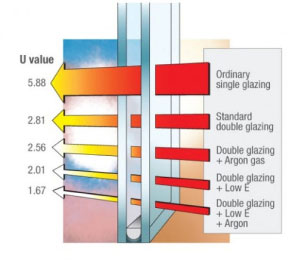

Before we go into measures for improving the energy performance, We need to understand what is U-value, or thermal transmittance Thermal transmittance, also known as U-value, is the rate of transfer of heat through a structure (which can be a single material or a composite), divided by the difference in temperature across that structure. The units of measurement are W/m²K. ( Watts / sq meter. kelvin ) U-values, measure how effective a material is as an insulator. The better insulated a structure is, the lower the U-value will be.To improve the energy performance following measures were implemented during the various charrette.

Roof Insulation

Before charrette as per the traditional way 150 mm RCC construction was decided for the roof of the building and U – value for that was 1.76 W/m2. K After charrette, we concluded to have 150 mm RCC construction and additional 100 mm extruded polystyrene( XPS ) insulation resulted in the reduction of U value of 0.31 W/m2.K from 1.76 W/m2. K

Glazing

Various options were available during selection of glasses. The project team emphasised the importance of daylight in the faster recovery of patients. Finally considering aspects like patient comfort, and cost, we selected double glazed units ( ie 6mm glass outside then 12 mm air gap and finally again 5 mm glass ) which is resulted in U – a value of 2.8 W/m2. K from 5.8 W/m2.k of single glazed windows.

External wall

Before charrette we were thinking about a 230 mm brick wall with plaster at both ends for external surface and U – value for that was 2 W/m2. KAfter charrette, we decided to have 150 mm Autoclave Aerated Concrete blocks with plasters on both sides instead of a 230 mm brick wall. This decision gave three advantages

- Easily available material at project site

- Less structural load than bricks

- Reduction of U – value from 2 W/m2. K to 0.9 W/m2. K

Free cooling

Ward floors have the provision of free cooling, which means if the outside air is suitable for space cooling, it can be directly be supplied without passing through the cooling coil.

Heat recovery wheels

These are installed along with Treated fresh air units installed at ward levels. These recovery wheels help in fresh air cooling.

Condenser water is used for reheating the air in AHUs for maintaining relative humidity.

Overall Energy Performance of Jupiter hospital Pune

At Jupiter Hospital, Thane ( 350 beds ) our EPI is around 238 Kwh/m2.y The annual Energy consumption of the hospital is around 65,00,000 kWh/y. During the execution phase, electricity consumption data of Jupiter Hospital, Pune for 12 months ( May 18 to April 19 ) was collected. During the monitoring period, two recovery floors were not operational so the overall operational area was 2,49,000ft2 with 219 operational beds and annual energy consumption was 31,37,520 kWh/y. We observed that the EPI of Jupiter hospital Pune is 136 Kwh/m2.y which is very close to predicated during charrettes.

Approximately additional cost incurred for energy efficient project of Jupiter Hospital, Pune.

| Sr.No. | Equipment Details | Cost in Rupees |

|---|---|---|

| 1 | Chiller with Variable frequency drive ( VFD ) v/s chiller without VFD | 1000000 |

| 2 | Chiller Plant Management software System v/s without plant manager | 600000 |

| 3 | Chiller Secondary Pump with VFD & IPS Control v/s without VFD and IPS control | 1714894 |

| 4 | Condenser hot water heat exchanger and Secondary Pump with VFD utilisation for Humidity control in Air Handling Unit | 152500 |

| 5 | TFA with heat recovery wheel vs regular Air handling units | 1400000 |

| 6 | BMS control system for 18 nos critical Air Handling Unit | 731509 |

| 7 | Heat Pump for Hot water | 1507275 |

| 8 | XPS insulation solution for building roof | 1800000 |

| 9 | Single galzed glass vs double glazed glass | 12600000 |

| Total | 21506178 |

Comparison between energy consumption of Jupiter Thane and Pune Hospital.

| Jupiter Hospital Thane | Jupiter Hospital Pune | |

|---|---|---|

| Operational beds | 350 | 250 |

| Annual electricity consumption ( units ) | 65.2 lacs | 31.48 lacs |

| Operational areas without parking and service floors | 27800 sq.meter | 23141 sq .meter |

| Energy performance index KWh/ m2 / year | 234 | 136 |

| Consumption of KWh/ bed.year | 18628 | 12552 |

BEEP has evaluated the energy performance of the building under the Bureau of Energy Efficiency (BEE) star rating of the hospital using the Energy Conservation and commercialization ( ECO ) bench tool. The result shows buildings qualify for a 4-star rating.Environment-friendly measures other than the HVAC system Environmental Protection Features adopted in the Engineering System Design and this design can be helpful for other hospitals to build an Environment-Friendly hospital in the country.

- Zero Liquid Discharge: It is a treatment process designed to remove all the liquid waste from a system. The focus of ZLD is to reduce wastewater economically and produce clean water that is suitable for reuse i.e: Gardening and Flushing system thereby saving money and being beneficial to the environment.

- Rainwater Harvesting System: Entire roof water is collected, filtered, and taken into the Rainwater Harvesting tank located inside the building thereby taking the direct benefit of the rainwater. External stormwater is collected and fed into the Rainwater harvesting pits thereby recharging the mother earth water. Rainwater harvesting for healthcare buildings, including hospitals, clinics and health centres and has the potential to save thousands of litres of rains water every year. This in turn can result in substantial cost savings and of course, contribute to alleviating stormwater run-off.

- Energy Saving Features: Vertical Transportation Elevators are selected with gearless drive motor and VFD control. This arrangement saves the energy consumed by elevators to the tune of 35%. Transformers are selected to meet the loss values permitted by the Energy Conservation Building Code published by the Bureau of Energy Efficiency of India. Entire light fixtures are selected with LED bulbs.

- Heat Pumps: used for hot water generation as well as we can use as a backup for humidity control of critical area air handling units.

- Presently, the Indian healthcare sector is passing through a transition and COVID-19 has posed a serious challenge. To deal with the new challenges, the sector needs to not only ramp up its health infrastructure but also bring in efficiency in every possible way. The energy-efficient or intelligent hospital is the key to better cost and care management.

Conclusion

- National Benchmark 200 KWh/ m2 / year (reference Bureau of Energy Efficiency, Govt. of India ECO-III project)

- Therefore in financial terms, Jupiter Hospital Pune is 64 KWh/m2/year more efficient as compared to the national benchmark.

- Translating into a financial savings of 64 KWh/ m2/ year x 23141 meter2 = 14,81,024 KWh so considering Rs 13 per KWh cost for electrical unit ; savings will be Rs 1.92 crores / year.

- The approximate additional cost incurred is around 2.15 crores for the energy-efficient project of Jupiter Hospital Pune.

Patients Speak

Hear the heartwarming stories of patients overcoming difficult afflictions

View Map

View Map Book an Appointment

Book an Appointment Find a Doctor

Find a Doctor Health Check-up

Health Check-up

Find a Doctor

Find a Doctor Health Checkup

Health Checkup Book an Appointment

Book an Appointment